Dust Extraction

Dust extraction is pretty important because my little workshop is the back room of my house - I don't want dust and swarf covering my workshop and spreading to the house. Unfortunately, the design of my gantry mill doesn't really allow it to be fully enclosed so I needed another option.

Dust Extraction

Phase 1

For my first few projects, I sat next to the mill and sucked up the dust by hand with my shop vac, chasing the cutter is it did its thing. A couple of times I wasn't paying attention and machined the vacuum nozzle, which luckily was plastic.

Phase 2

The next step was to permanently attach the vacuum hose to the gantry and point the vacuum nozzle at the cutter. I used cable ties to hold the hose to the side of the die grinder, but it became annoying re-doing this every time I changed the spindle, or put in a different size cutter. The cables didn't hold the hose very tightly which caused the nozzle to move as the gantry moved.

Phase 3

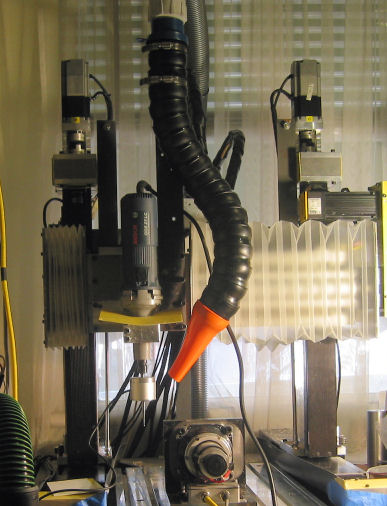

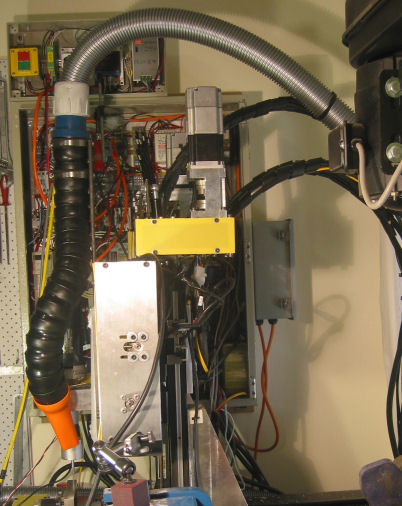

I invested in some Loc-Line modular vacuum hose. This is like the typical modular hose used to squirt coolant on the mill/drill, but instead of a ¼" internal bore, this stuff is 2 ½". A front on and side shot of the hose is shown below.

The Loc-Line hose is the black snaky looking thing with an orange nozzle. The black hose is the slightly more expensive anti-static version (it is normally blue). This is connected up to the silver coloured dust extraction hose. The modular hose is clamped using 3" hose clamps at the top of a 50x8mm steel bar. The modular hose has a 5 ¾" bend radius which means the bar it is attached to had to be tall to provide adjustment room.

The Loc-Line modular hose is super expensive... if you buy it in Australia! Australian prices are about 4 times the US prices. I bought mine from www.modularhose.net, which is the international shop front for ModularHose. One piece of vacuum hose plus shipping from the US is about the same as a piece in Australia. As soon as you add a second piece, you're in front.

Dust Separation

My shop vac, a Festool CT-11e, is a very powerful and expensive shop vac. It was expensive to repair when the motor blew, and the dust bags and other accessories are very expensive. To keep the running costs down, I decided to add a cyclonic separator to the system.

There is a great web site, Bill's Cyclone Dust Collection Research, where Bill Pentz outlines the dangers of dust, and shows how to build a cyclonic separator. The separator extracts almost all dust and other particles from the air stream and dumps them in a barrel; no more bags!

I started planning my cyclone. I liked the idea of building it out of clear polycarbonate so I could see it working, like the ones for sale at Clear Vue Cyclones, Inc. Unfortunately my plastics manufacturing skills are pretty minimal, so I just bought one from Clear Vue, the mini CV06, made for shop vacs (they mainly do large wood shop extraction sytems). The installed unit is shown in the picture below.

Only the device that looks like a blender is the CV06. I had to add the bucket; which sounds like a simple task, but it wasn't. I started with a plastic one from Bunnings. When I fired it up for the first time, the vacuum was so powerful, it just crushed the bucket. I had to replace it with a metal bucket with an air tight lid. I found one at The NCI Packaging Shop. Amazingly, a 25 litre metal pail with lid and air tight locking ring was cheaper than the plastic pail from Bunnings.

Amazingly (again), the separator and Loc-Line hose all fit the Festool shop vac. This is amazing because I have only ever been able to use Festool accessories with the vac.

In the picture above, the clear polycarbonate is all fogged up. That's because I was extracting aluminium chips and spraying the cutter with WD40 to prevent it from gumming up. After cutting some wood, it started to clear.