Box

I made a box! Not terribly exciting but it was made using the whole CAD/CAM process.

Step 1 CAD

Here's the design of my box. You can click on the image to bring up the 3D pdf file.

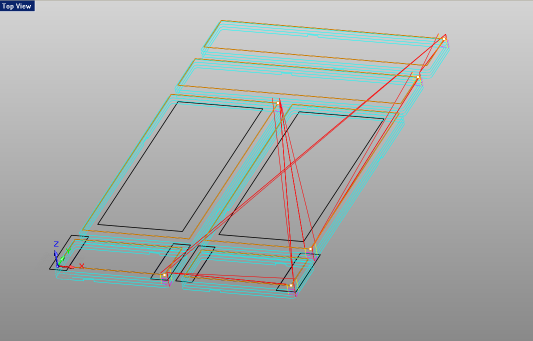

Step 2a CAM Design

The machining steps are designed using Visual Mill. My CNC mill has a cutting area of approximately 300 x 500 x 300 mm, so the parts were broken up into two sheets. Sheet one is shown below.

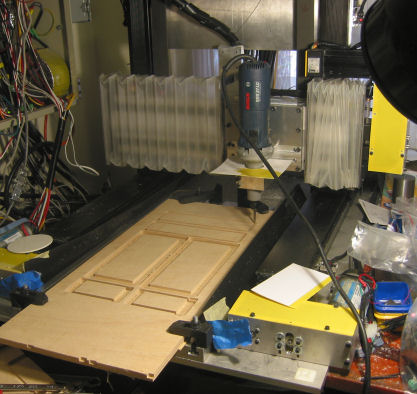

Step 2b Manufacture

The box parts are machined. The photo below shows the end of machining of sheet one. It took about an hour. The speed was really slow (1000mm/min) and I only took small cuts (3-4mm passes). When I get a little braver, I'll take more agressive cuts.

All the parts.

Step 3 Assembly

Here's an action shot showing the box holding the drill chuck as it was designed.

It didn't assemble as nicely as I had hoped. I didn't clamp it together very well, so the lid and base aren't very flush. But it works well enough.

Those with a keen eye will have noticed that I put the lid on backwards. The small gap for the spanner is supposed to be at the back of the box. Oops!