3d Printed Harmonic Gearboxes

The “goto” zero backlash gearbox for hobbyists is normally the harmonic gearbox (strain wave gearbox). There are many geometric variants of this gearbox made by manufacturers such as Harmonic Drive. These are expensive gearboxes (I’ve heard $2k in small quantities), and are still very pricey second hand on ebay.

The big advantage of these gearboxes is zero backlash and huge reduction ratios (100:1) in a single stage.

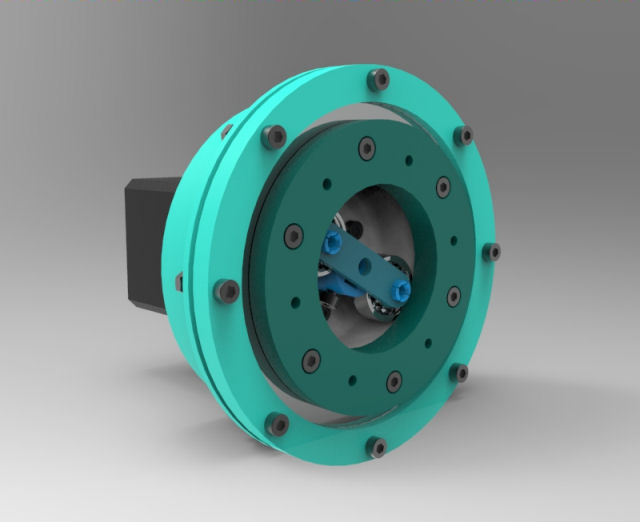

This is the first type that I tried to 3d print. Clicking on the image opens a 3D pdf with animated exploded views (click on the text labels in the pdf)

I printed the flex spline using nylon. That worked really well; it was flexible and tough.

However, the real problem I had was the whole mechanism flexing. If the wave generator didn’t push hard enough against the flex spline/circular spline, there would be slipping. Increasing the pressure (moving the small bearings further out) then caused the whole case to flex and wobble. Sadly I don’t have any video shots of this.

At this point I gave up, and decided to try something different.