3d printed Hypocycloidic gearboxes IV

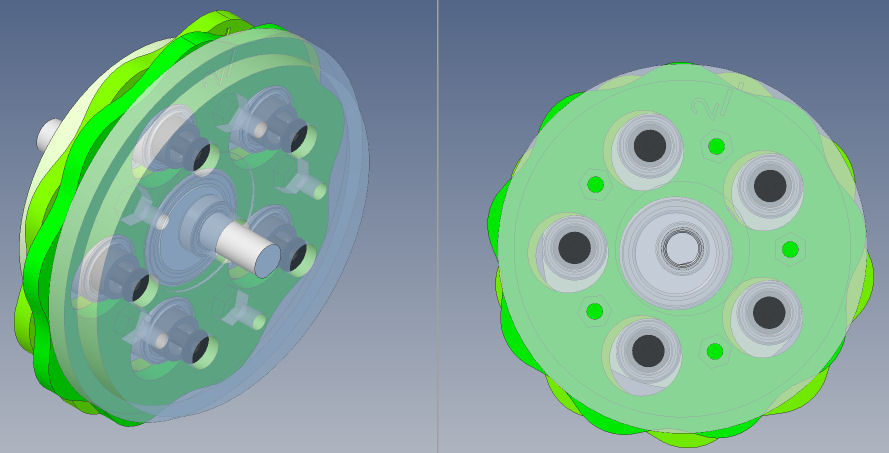

If a hypocycloid gearbox is driven quickly, the eccentric driving the cam will cause vibrations. An easy fix for this is to drive 2 cams, mirrored in their action.

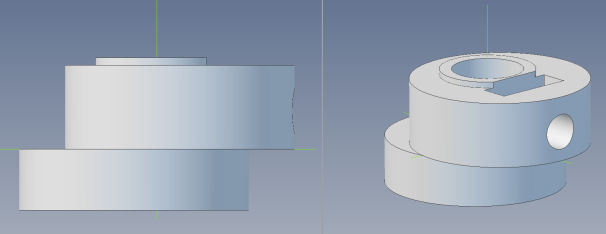

This means the eccentric, needs to be a dual eccentric…

As there are now 2 cams, this means twice as many bearings, for both the roller pins, and the output drive. This model has 20 MR128 8x12x3.5mm bearings for the roller pins, another 10 in the output, 2 6702 15x21x4mm bearings on the eccentric, and 3 SMR106 6x10x3mm bearings holding the assembly concentric on the main shaft.

Which turns out to be one of the cool features of this gearbox; because everything runs concentrically, the gearbox can effectively be mounted on a shaft, whether directly on the end of a motor shaft, or on the axle of a robot joint. (The robot joint has a belt drive 1:3 reduction, and the hypocyclodic is 1:9, giving a total reduction of 1:27)